Haver & Boecker oHG

Booth number: HALL 1 - G021a

www.haverboecker.com

About us

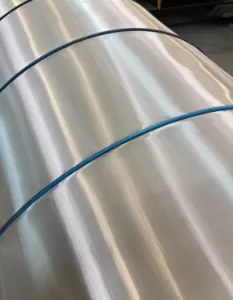

Haver & Boecker is one of the world's leading manufacturers of wire mesh for industry and technology. As a medium-sized family managed business, we have played a decisive role in shaping the technology of wire weaving for more than 135 years.

We develop and use innovative manufacturing processes to fabricate wire cloth into filters and fabricated parts for filtration or cleaning, for the protection of people or sensitive electronics, or for the uniform flow of a gaseous, liquid, or solid medium.

These products are used in many different industries - from the automotive industry to the energy and environmental sectors.

A look at mechanical water filtration, for example, shows: metal wire mesh is a reliable and durable filter medium in all treatment plants, as it combines maximum durability and the highest precision.

Address

Ennigerloher Str. 64

59302 Oelde

Germany

E-mail: bd@haverboecker.com

Phone: +49 2522 30 433

Internet: www.haverboecker.com

Contact person:

Tim Gerdes

Business Development - Project Manager Water Filtration

E-mail: t.gerdes@haverboecker.com

Phone: +49 2522 30-162

Products & Services

With the production of water filters made of metal wire mesh in smallest and largest dimensions, our focus is on efficient mechanical water filtration.

In numerous applications in the water industry, the optimum combination of throughput and filtration fineness is crucial: for the retention of microplastics and for the treatment of wastewater or sea water. In recirculating aquaculture systems (RAS), mechanical filtration using drum filters is also a key element for maintaining stable water quality, healthy fish stocks, and efficient operation.

Metal wire mesh enables the filtration of even finest particles. Corrosion resistance, suitability for welding and stability are further examples of concrete requirements for the development of water filters that we have already been able to successfully meet with the use of metal wire mesh.

We fulfil individual product requirements with a wide range of proven products or with solutions that are newly developed for special applications. These include new weave types, automation solutions, and conceptualising the optimum production and testing process.

Wastewater filters for microscreen systems

Precise mechanical filtration of the water is a decisive factor in also achieving efficient and, thus, economical, but above all, sustainable treatment processes when treating water - this also applies to wastewater. Wire mesh wastewater filters from Haver & Boecker can be easily integrated into existing treatment plants as filter candles, flat sieve mesh, or filter plates and offer impressive performance thanks to their high throughput, extremely fine pore sizes, stability and corrosion resistance.

Retrofit Panels for drum filters with MINIMESH® RPD HIFLO-S

Retrofit filter panels featuring the patented metal filter cloth are the result of a close development partnership with our collaborator Renasys. These panels especially excel in fine filtration (≤ 40 µm), offering exceptionally high throughput and outstanding dirt-holding capacity.

Avesta 254 SMO mesh laminates for demanding seawater applications

With POROSTAR® wire mesh laminates made from Avesta 254 SMO, Haver & Boecker is setting a new standard for seawater-resistant filter elements. This high-alloy stainless steel achieves an exceptionally high corrosion resistance with a PREN value of 43 – ideal for use in saline media. The sintered mesh laminates combine the strengths of surface and depth filters. Particles are precisely retained on the surface, while the multilayer structure enables high dirt-holding capacity.